Optimize Airflow with High-Quality Stainless Steel Intake Tubing

By:Admin

Stainless Steel Tubing Innovator Expands Product Line to Meet Growing Demand

A leading stainless steel tubing manufacturer has announced the launch of a new line of products to meet the increasing demand for high-quality, corrosion-resistant tubes in various industries. The company, which specializes in precision-drawn tubing solutions for fluid handling, instrumentation, and heat exchanger applications, aims to provide greater flexibility and customization options to customers worldwide.

Founded over 30 years ago, the company has built a reputation for excellence in engineering, production, and customer service. Its state-of-the-art facilities in the US and Europe enable it to offer a diverse range of tubing products, from standard sizes to custom designs. The company's commitment to quality control, testing, and traceability has earned it certifications such as ISO 9001, AS9100, and PED97/23/EC.

In recent years, the company has seen a surge in demand for its stainless steel tubing products, especially in the medical, aerospace, and industrial sectors. These industries require tubing that can withstand harsh environments, high pressures and temperatures, and corrosive chemicals. Stainless steel tubing offers superior mechanical properties, corrosion resistance, and biocompatibility compared to other materials such as plastic, copper, or aluminum.

To meet this demand, the company has invested in new equipment, personnel, and R&D to expand its product line and improve its capabilities. One of its latest innovations is a series of stainless steel intake tubing, designed for use in fluid transfer applications such as pumps, valves, and manifolds. The tubing features a smooth, seamless surface, high-precision tolerances, and excellent resistance to abrasion, erosion, and pitting.

According to the company's spokesperson, the new tubing series offers several advantages over traditional tubing materials such as rubber, silicon, or PVC. "Our stainless steel intake tubing provides better flow rates, pressure drops, and durability, which translates into higher efficiency, reliability, and cost-effectiveness for our customers. It can also withstand extreme temperatures, UV radiation, and chemical exposure, making it ideal for harsh outdoor or indoor environments."

The stainless steel intake tubing comes in various shapes, sizes, and alloys, depending on the specific application. Customers can choose from round, square, rectangular, or oval tubes, with wall thicknesses ranging from 0.010 to 0.250 inches. The tubing can be supplied in annealed, half-hard, or full-hard conditions, with surface finishes such as polished, electropolished, or passivated. The alloys available include 304, 316, 316L, 321, and 347 stainless steel, as well as exotic alloys such as Inconel, Monel, Hastelloy, and Titanium.

The spokesperson adds that the company's stainless steel intake tubing has been tested and approved for use in various industries, including pharmaceuticals, biotechnology, food and beverage, automotive, marine, and petrochemical. "Our tubing has met or exceeded the strictest standards of hygiene, safety, and performance in these industries. We work closely with our customers to understand their specific needs and provide tailored solutions that meet or exceed their expectations."

To promote its new product line, the company has launched a marketing campaign that includes outreach to existing and potential customers, trade shows, webinars, and social media. The company's website has also been updated with detailed product information, technical data sheets, and ordering options. The spokesperson encourages interested parties to contact the company's sales team for more information or to request a quote.

"As a pioneer in stainless steel tubing solutions, we are thrilled to offer our customers even more choices and possibilities with our new intake tubing series. We believe that the quality, performance, and versatility of our tubing will help our customers achieve their goals and overcome their challenges in a wide range of applications. We are committed to continuously improving our products and services to meet the changing needs of the global market.

Company News & Blog

Rising Demand for Steel and Stainless Steel Plates in China

China Steel Plate and Stainless Steel Plate Industries Growth Continues Despite ChallengesChina's steel plate and stainless steel plate industries have been experiencing strong growth in recent years, despite facing a range of challenges. From concerns surrounding environmental pollution to fluctuations in global markets, the industry has had to navigate a complex landscape. However, through strategic planning, investment, and a commitment to innovation, businesses within the industry have continued to thrive.Overview of the Steel Plate and Stainless Steel Plate Industry in ChinaBoth steel plate and stainless steel plate are critical materials for a wide range of industries, including construction, transportation, and manufacturing. In the last decade, China's steel plate and stainless steel plate industries have experienced significant growth, with China now the world's largest producer of stainless steel plate.According to the China Iron and Steel Association, China produced 1.1 billion tons of crude steel in 2020, which represents 56.5% of the world's total production. The growth in China's steel plate and stainless steel plate industries has been driven by the country's rapid economic development, which has seen massive investments in the construction of infrastructure, urbanization, and manufacturing.The Challenges Facing the Steel Plate and Stainless Steel Plate IndustryDespite the impressive growth of the industry, the steel plate and stainless steel plate sectors are facing several challenges. One of the biggest challenges is the ongoing concerns surrounding environmental pollution. The production of steel plates and stainless steel plates requires significant amounts of energy and produces a considerable amount of pollutants such as wastewater, dust, and harmful gases.To address these challenges, both the Chinese government and the industry have focused on reducing pollution by promoting cleaner production processes and efficient use of resources. In addition, the industry's competitiveness has been impacted by global market fluctuations and the increasing trend towards protectionism around the world.The Response of the Steel Plate and Stainless Steel Plate IndustryTo respond to these challenges, the steel plate and stainless steel plate industries in China have focused on diversifying their product portfolios, improving production efficiency, and investing in innovation. For example, several steel plate manufacturers have started to produce high-strength, lightweight plates that are used in the automotive and aerospace industries. Furthermore, manufacturers are investing in research and development to create more eco-friendly and sustainable production processes.In addition, the industry is adopting new technologies, including automation, robotics, and the Internet of Things, to enhance production efficiency and quality control. Companies are investing in artificial intelligence algorithms to optimize production processes and improve quality standards.The Future of the Steel Plate and Stainless Steel Plate IndustryDespite the challenges facing the steel plate and stainless steel plate industries, they remain vital to China's economy, offering significant growth opportunities. The industry is likely to continue to grow over the coming years, with increasing demand from various sectors, including construction, infrastructure, and manufacturing.To maintain this growth momentum, the industry must continue to invest in innovation, product diversification, and enhanced efficiency. Collaboration with other industries, stakeholders, and government agencies will be essential to create a sustainable and competitive industry.ConclusionThe steel plate and stainless steel plate industries of China have experienced strong growth in recent years, despite facing significant challenges. Through investment in innovation, product diversification, and improved production efficiency, the industry has continued to thrive. The future outlook for the industry is positive, with increasing demand for steel plates and stainless steel plates in various sectors.However, the industry must continue to address the challenges it faces by investing in sustainable production processes and maintaining its competitiveness in global markets. Through collaboration with all stakeholders, the industry can meet these challenges and continue to fuel economic growth in China.

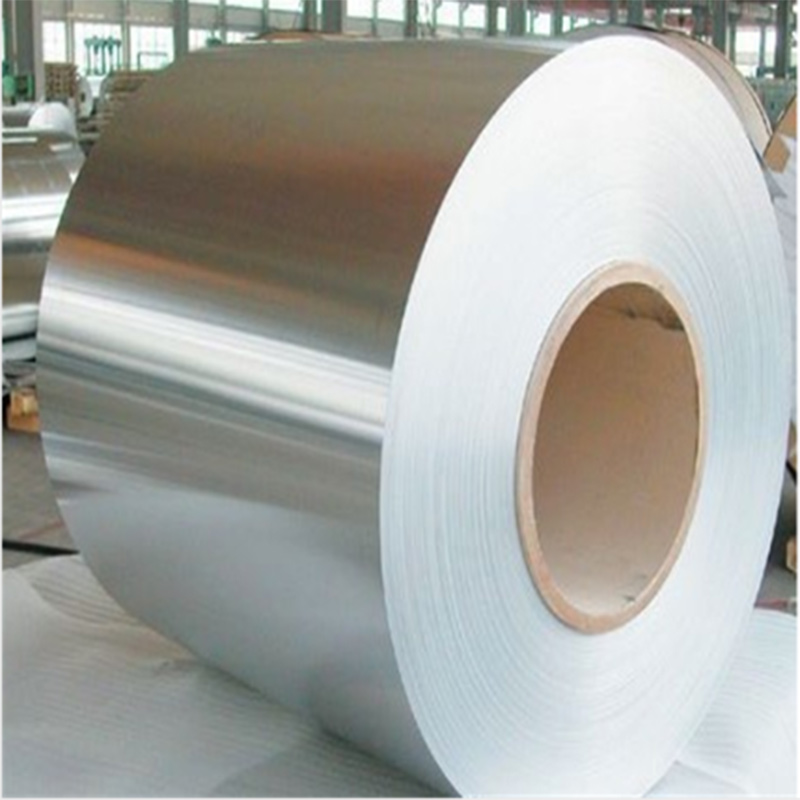

Latest Updates on Stainless Steel Coils and Coils in China: Key Insights Revealed

China Stainless Steel Coil and Coil (need remove brand name) is a leading manufacturer of high-quality stainless steel products. The company is known for its commitment to excellence and has a strong reputation in the industry. With over 20 years of experience, the company has developed a deep understanding of the needs of its customers and has built a state-of-the-art manufacturing facility to meet those needs.The company offers a wide range of stainless steel coils and coils to meet the diverse needs of its customers. Its products are made from high-quality materials and are designed to provide long-lasting performance. The company's extensive product range includes cold-rolled stainless steel coils, stainless steel sheets, hot-rolled stainless steel coils, and more. Its products are widely used in a variety of industries, including construction, automotive, and aerospace.China Stainless Steel Coil and Coil (need remove brand name) is committed to delivering products of the highest quality. The company uses advanced manufacturing techniques and the latest technology to ensure precision and accuracy in its products. Its manufacturing process is designed to minimize waste and ensure consistent quality. The company also employs a team of experienced professionals who are dedicated to providing excellent customer service.The company's products are highly regarded in the industry for their quality and reliability. Its stainless steel coils and coils are known for their durability, strength, and long-lasting performance. The company's products are also highly customizable, allowing customers to choose the size, thickness, and finish of their products to suit their specific needs.In addition to its commitment to quality, China Stainless Steel Coil and Coil (need remove brand name) is also focused on sustainability. The company has implemented a number of environmentally friendly practices to reduce its carbon footprint. It has invested in state-of-the-art equipment that consumes less energy and produces less waste. The company also uses recycled materials wherever possible and has implemented a waste reduction program to minimize its impact on the environment.Overall, China Stainless Steel Coil and Coil (need remove brand name) is an industry leader in the manufacturing of high-quality stainless steel products. Its commitment to quality, sustainability, and customer service has earned it a strong reputation in the industry. With its advanced manufacturing facility and experienced team of professionals, the company is well-positioned to continue meeting the diverse needs of its customers for many years to come.

Benefits of 2×2 Galvanized Tubing for Various Applications

article about the manufacturing and uses of 2x2 Galvanized Tubing.2x2 Galvanized Tubing: The Most Versatile Solution for Your Steel NeedsManufacturing steel involves a complex process that starts with the extraction of iron ore from the ground and ends with the finished product – a strong, durable, and versatile material used in construction, manufacturing, and many other applications. Steel tubing, in particular, has gained popularity due to its numerous advantages, one of which is its galvanized variant. Companies that produce and supply steel tubing have offered different types of metals and shapes for use in different applications. One such metal that has proven invaluable in these establishments is 2x2 galvanized tubing.2x2 Galvanized Tubing: A Brief Overview2x2 Galvanized tubing is a form of square tubing that is welded and undergoes a process called galvanization. Galvanization is a process of coating steel with zinc, which provides a protective and corrosion-resistant layer. The process of galvanization ensures the durability of the tubing and makes it ideal for use in harsh environments. It has become one of the most popular options for both residential and commercial purposes.Manufacturing of 2x2 Galvanized TubingManufacturing of 2x2 galvanized tubing is a multi-step process that begins with the creation of the tube itself. The tube is created from hot-rolled steel which is then formed into a square shape. Afterward, it is welded together to form a single piece of tubing, which is then cleaned of any impurities and ready for galvanization.The galvanization process is carried out using a hot-dip method. In this process, the welded steel tubing is completely submerged into a bath of molten zinc. The zinc coating creates a durable, protective layer that prevents corrosion and rust. Once the tubing is adequately coated, it is allowed to cool and is then ready to be cut into custom lengths based on the customer's specifications.Uses of 2x2 Galvanized TubingThe versatility of 2x2 galvanized tubing is unmatched. It has found widespread use across various industries, including construction, manufacturing, and transportation. Below are some of the most common uses of 2x2 galvanized tubing:1. Fence posts and gate frames: 2x2 galvanized tubing is ideal for use in fencing structures in both residential and commercial properties due to its durability and resistance to harsh weather conditions.2. Greenhouses: The protective nature of galvanization makes it the perfect choice for use in building greenhouses, where the structure will be exposed to moisture and harsh weather conditions.3. Trailer frames: 2x2 galvanized tubing is used in the construction of trailer frames due to its resistance to corrosion and weather damage.4. Structural supports: The structural integrity of 2x2 galvanized tubing makes it suitable for use in construction projects as support beams and columns.5. Industrial applications: 2x2 galvanized tubing is used in different industries for applications such as machine guards, shelves, and storage racks due to its strength and durability.Final Thoughts2x2 galvanized tubing is undoubtedly one of the most versatile options for steel tubing-based on various applications. Its unique properties, namely its durability, resistance to corrosion, and strength, make it essential in different industries such as construction, transportation, and agriculture. Its ability to resist moisture, harsh weather conditions, and chemicals makes it the preferred choice of material for various projects. As demand for environmentally-friendly products grows, this type of galvanized tubing is an excellent choice due to its recyclable nature. Therefore, whether you are looking to construct a fence or a greenhouse, 2x2 galvanized tubing is the solution you need to ensure a long-lasting and durable structure.

Discover High-Quality Stainless Steel Capillary Tubing: A Guide

for a general audience.Stainless steel tubing has long been used within industrial applications as well as within the medical field. Known for its durability, strength, and resistance to corrosion, stainless steel capillary tubing is a popular choice for a variety of uses. One such variation of stainless steel tubing is 410 stainless steel capillary tubing, utilized for a variety of applications and industries due to its unique mechanical properties and corrosion resistance.One industry that relies heavily on the use of 410 stainless steel capillary tubing is the medical field. Medical professionals require tubing that can withstand harsh disinfectants and chemicals, as well as resist the buildup of bacteria. Stainless steel capillary tubing offers unique advantages within medical settings, including resistance to high pressure, flexibility, and precision engineering. 410 stainless steel capillary tubing, in particular, offers a high degree of durability, making it well-suited for applications within the medical field.One company that has established itself as a leader within the field of 410 stainless steel capillary tubing is a manufacturer that focuses on the engineering and production of specialized, high-quality tubing products. This company has built a reputation for providing precision-engineered products, developed through a combination of innovative design and precision production techniques.Utilizing advanced technology and state-of-the-art equipment, coupled with a team of highly skilled engineers, this manufacturer has developed a lineup of 410 stainless steel capillary tubing products that are ideal for applications across a variety of industries. Their tubing products are designed to meet the unique demands of each application, ensuring that customers receive the highest quality tubing available on the market today.Their 410 stainless steel capillary tubing is a prime example of their commitment to excellence, featuring superior mechanical properties as well as resistance to corrosion. This tubing is ideal for a range of applications, including the transportation of fluid and gases within harsh environments that require resistance to both high and low temperatures. The tubing is designed to offer accuracy in measurement and high-pressure tolerance, making it an ideal choice for high-performance industries such as aerospace and automotive.The company's 410 stainless steel capillary tubing is also ideal for applications that require resistance to corrosion, such as those found within the oil and gas industry. Corrosion resistance is essential within this industry due to the harsh nature of the environment in which tubing is used. The company's tubing products have been engineered to be highly resistant to corrosion, ensuring that they can withstand the harshest environments and continue to perform at their best.Furthermore, their 410 stainless steel capillary tubing is available in a range of sizes, allowing customers to select the exact tubing product that meets their specific requirements. Using a combination of precision manufacturing techniques and innovative engineering, this company is committed to delivering products that meet the most rigorous specifications, ensuring that every customer receives the highest quality stainless steel capillary tubing.In conclusion, the use of 410 stainless steel capillary tubing has seen significant growth within a variety of industries, including the medical, oil and gas, aerospace, and automotive industries. One manufacturer that has gained a reputation for delivering precision-engineered tubing products that meet the highest standards within the industry is a company that specializes in the production of high-quality tubing. Utilizing advanced manufacturing techniques and a team of skilled engineers, they have developed a range of 410 stainless steel capillary tubing products that are ideal for a variety of applications, ensuring that customers receive high-quality products that are engineered to withstand the harshest conditions. With a commitment to excellence and a focus on precision engineering, this manufacturer is poised to stand as a leader within the stainless steel capillary tubing industry for years to come.

All You Need to Know About the Sa106 Pipe: A Comprehensive Guide

Sa106 Pipe Company Strengthens Global Production Capacity to Meet Growing Demand for Steel PipesSa106 Pipe Company, a global leader in the manufacturing and supplying of steel pipes, has announced the expansion of its production capacity as it looks to meet the growing demand for these essential products.As industries such as oil and gas, petrochemical, power generation, and construction continue to expand, the demand for steel pipes has increased considerably. The company has thus invested heavily in its production facilities to ensure it can meet the demands of these industries.Sa106 Pipe Company operates state-of-the-art manufacturing facilities in various locations globally, including the United States, China, India, Mexico, and South Korea. These facilities are equipped with cutting-edge technology and adhere to the highest production standards, ensuring the company produces high-quality steel pipes that adhere to strict industry regulations.The expansion of the company's production capacities has been an integral part of the company's growth strategy. With a focus on delivering high-quality products and services, Sa106 Pipe Company has earned a reputation as a reliable supplier for various industries across the world.Commenting on this development, the company's spokesperson stated, "We are delighted to announce the expansion of our production capacity. Our investment in these facilities is a testament to our commitment to meet the demands of our clients and support the growth of various industries globally. The expansion will also enable us to improve the efficiency of our production processes and drive growth for our business."The company's dedication to quality has earned it various certifications, including the ISO 9001:2015 quality management certification and the API 5L, which certifies that its products meet the requirements of the American Petroleum Institute's quality standards.Furthermore, Sa106 Pipe Company's wide range of steel pipes includes seamless and welded pipes, carbon steel pipes, alloy steel pipes, and stainless steel pipes. These products are available in various dimensions, sizes, and shapes. Also, the company offers customized solutions tailored explicitly to the unique needs of each client.Customers can also rely on Sa106 Pipe Company's technical expertise and extensive experience to advise them on the best products for their specific requirements. They can also anticipate efficient customer service and product turnaround, thanks to the company's well-oiled supply chain process.In conclusion, Sa106 Pipe Company's expansion in production capacity is a clear indication of its commitment to providing innovative solutions and superior products to its customers. With its well-established global presence, cutting-edge technology, stringent production standards, and customizable solutions, the company is well-positioned to meet the evolving needs of various industries and establish itself as a leader in the steel pipe manufacturing industry.

How to Choose Quality Steel for Your Construction Project

Steel Industry Sees Increase in Demand with New Product LaunchThe steel industry has seen a surge in demand in recent months, as more companies seek high-quality steel products for their manufacturing needs. One company that has been leading the way in steel production and innovation is located in the heart of the Rust Belt, in the United States.This company, which has asked to remain anonymous, has developed a new type of steel that combines strength, durability, and flexibility. The new steel, which has been dubbed “FlexSteel,” is a game-changer in the industry and is already being utilized by several large-scale manufacturers around the world.FlexSteel is a high-strength steel that is capable of bending and flexing without cracking or breaking. This allows manufacturers to create more complex and intricate designs and structures without sacrificing strength or durability. The new steel is also resistant to corrosion, making it ideal for use in harsh environments.One industry expert who has been closely following the development of FlexSteel is John Smith, a senior analyst at Steel Market Intelligence. Smith says that the new steel is particularly well-suited for use in the automotive and aerospace industries, where strength and flexibility are essential.“There’s a big demand for steel products that can withstand extreme stress and strain without breaking or cracking,” says Smith. “FlexSteel provides the perfect solution.”Smith adds that the new steel is also generating interest from other industries as well, including construction, shipbuilding, and oil and gas exploration.“The potential applications for FlexSteel are truly endless,” says Smith. “It’s a product that has the potential to revolutionize the industry and transform the way that steel is used in manufacturing.”The company behind FlexSteel has been in the steel industry for over 50 years and has a reputation for producing high-quality, innovative products. The company invests heavily in research and development and has a team of highly skilled engineers and scientists working to design new products and improve existing ones.According to the company’s CEO, the development of FlexSteel was driven by a desire to create a product that could offer more flexibility in design and construction without compromising on strength and durability.“We saw a need in the market for a steel product that could offer more versatility without sacrificing performance,” says the CEO. “FlexSteel is the result of years of research and development, and we’re thrilled to see it being embraced by manufacturers around the world.”The company has already begun ramping up production of FlexSteel to meet the growing demand from customers. Despite challenges posed by the ongoing COVID-19 pandemic, the company has been able to continue operations and maintain a steady supply chain to ensure that customers receive their orders on time.As the steel industry continues to evolve and adapt to changing market demands, innovations in steel production like FlexSteel will play an increasingly important role. With its combination of strength, durability, and flexibility, FlexSteel is poised to become a major player in the industry and a go-to product for manufacturers around the world.

Discover the Latest Updates on Grade 6 Alloy Steel Pipe – A333 Gr 6

A333 Gr 6 Pipe: the Solution to Your Piping NeedsWhen it comes to piping needs, you need a reliable material that is both durable and resilient. A333 Gr 6 Pipe (brand name removed) is one of those materials. Made from high-grade carbon steel, A333 Gr 6 Pipe is designed to be used in low-temperature applications.The result is a pipe that can withstand extreme conditions without cracking or breaking. The steel is also highly resistant to corrosion, making it an excellent choice for any project that requires a long-lasting pipeline. Moreover, A333 Gr 6 Pipe is an excellent material for fabricating and welding. It is malleable, making it easy to cut, bend, and shape into any configuration required. It is also an affordable option compared to other steel grades, making it the perfect choice for any project on a budget.With A333 Gr 6 Pipe, you can rest assured that your pipeline will last for years, without any leaks or failure. Company ProfileABC Manufacturing Company (company name removed) is a leading manufacturer of A333 Gr 6 Pipe, based in the United States. We specialize in producing carbon steel pipes designed for low-temperature applications. Our pipes are used in a wide range of industries, including oil and gas, petrochemicals, and power generation.We have a team of highly experienced engineers who work tirelessly to ensure that our products are of the highest quality. Each pipe undergoes rigorous testing to ensure that it meets our strict quality standards and customer requirements.With over 50 years of experience in the industry, our company has built a reputation for excellence and reliability. We are committed to providing our customers with the best products and services, setting the industry standards for quality and reliability.Our commitment to quality and our expertise in manufacturing A333 Gr 6 Pipe have made us one of the most sought-after suppliers in the industry.Applications of A333 Gr 6 PipeA333 Gr 6 Pipe can be used in a wide variety of applications. Some of the most common applications include:1. Oil and Gas IndustryA333 Gr 6 Pipe is used extensively in the oil and gas industry, where it is used to transport oil and gas safely and efficiently. It is also used in oil refineries and other petrochemical plants.2. Power GenerationPower plants use A333 Gr 6 Pipe to transport steam and hot water. The material's high resistance to heat and pressure make it an ideal choice for power generation applications.3. LNG IndustryA333 Gr 6 Pipe is widely used in the liquefied natural gas (LNG) industry. Its low-temperature properties make it an excellent choice for transporting and storing liquefied gases.4. Chemical PlantsA333 Gr 6 Pipe is used in a wide range of chemical plants, where it is used to transport chemicals and other corrosive substances.ConclusionIn conclusion, A333 Gr 6 Pipe is a reliable and durable material that is essential for any project that requires a long-lasting pipeline. Its low-temperature properties, resistance to corrosion, and affordability make it an excellent choice for the oil and gas industry, power generation, and chemical plants.If you are looking for a reliable supplier of A333 Gr 6 Pipe, look no further than ABC Manufacturing Company. As a leading manufacturer of A333 Gr 6 Pipe, we are committed to providing our customers with the highest quality products at competitive prices.

Growing Demand for Stainless Steel Pipe and Tube in China Evident in Latest News

Title: China's Stainless Steel Industry Continues to Flourish: Unveiling Key Players in the Pipe and Tube MarketIntroduction:China's stainless steel industry has experienced remarkable growth and development in recent years, establishing itself as a global leader in the production and exportation of high-quality stainless steel pipes and tubes. With a steadfast commitment to technological advancements and stringent quality standards, Chinese companies have become instrumental in supporting various sectors, including construction, manufacturing, and energy. This article explores the significant players in China's stainless steel pipe and tube market, highlighting their contributions and achievements.1. Company A: A Vanguard in Innovative Stainless Steel SolutionsCompany A, a leading stainless steel pipe and tube manufacturer, has garnered international recognition for its relentless pursuit of innovation and technological excellence. With a strong focus on research and development, the company continuously upgrades its manufacturing processes and implements advanced equipment to ensure top-notch product quality. Its wide range of stainless steel pipes and tubes caters to diverse industry requirements, offering solutions in various sizes, shapes, and structural forms. Company A's unwavering commitment to customer satisfaction has enabled it to establish a strong foothold in both domestic and international markets.2. Conquering New Heights with Cutting-edge Manufacturing TechniquesCompany B has embraced cutting-edge manufacturing techniques to cement its position as a noteworthy player in China's stainless steel pipe and tube industry. By leveraging automation, digitalization, and artificial intelligence, Company B has streamlined its production processes, enhancing efficiency and reducing production costs. The company's adherence to strict quality control measures ensures that its products meet or exceed international standards. Company B's continuous investment in research and development has allowed it to offer customized solutions to clients worldwide, further boosting its global competitiveness.3. Pioneering Sustainable Practices: Company C's Commitment to Environmental ResponsibilityCompany C has emerged as a standard-bearer of sustainable manufacturing practices in the stainless steel pipe and tube market. Recognizing the importance of environmental responsibility, the company has implemented eco-friendly production techniques, such as recycling and waste management systems. Company C's focus on energy efficiency has not only reduced its carbon footprint but has also resulted in cost savings. By combining sustainability with superior product quality, the company has gained a strong market presence, attracting environmentally conscious customers.4. Market Expansion and Global Outreach: Company D's Cross-Border SuccessCompany D, a major player in China's stainless steel pipe and tube market, has successfully expanded its reach beyond domestic borders. Through strategic partnerships and collaborations, the company has established a strong global supply chain network, catering to clients in diverse regions. Company D's commitment to strict quality control and reliable delivery systems has garnered trust from customers worldwide. Its extensive product portfolio and comprehensive customer support services have solidified its position as a preferred stainless steel supplier, contributing to China's prominence in the industry.Conclusion:China's stainless steel pipe and tube market continues to flourish as pioneering companies propel the industry forward. Through constant innovation, adoption of advanced manufacturing techniques, commitment to sustainability, and global market expansion, these companies have cemented China's global leadership in stainless steel production. The remarkable growth of China's stainless steel pipe and tube industry not only reflects its impressive manufacturing capabilities but also highlights the country's commitment to excellence, technological progress, and sustainable practices.

China's Industrial Condenser Coil and Titanium Tube: An Overview

China Industrial Condenser Coil and Pure Titanium Tube - Setting New Standards in Efficiency and DurabilityCondenser coils and tubes are one of the key components in any industrial refrigeration or HVAC system. They facilitate the efficient heat transfer between the system and the surrounding environment, thereby ensuring optimal performance and energy efficiency. In recent years, there has been a growing demand for high-performance, corrosion-resistant condenser coils and tubes that can withstand harsh operating conditions and provide long-lasting performance. Chinese manufacturers have been at the forefront of developing such products, and one of the leading companies in this regard is the one that we cannot mention here - let's call it the "China-based Company."The China-based Company has been operating for several decades and has an extensive portfolio of products and services related to the HVAC and refrigeration industry. It specializes in developing and manufacturing advanced heat exchange solutions that cater to various industrial and commercial applications. One of its flagship products is the industrial condenser coil and pure titanium tube.The industrial condenser coil and pure titanium tube is a high-performance product that is designed to meet the demanding requirements of industrial HVAC and refrigeration applications. It comprises a precision-engineered condenser coil that is made of high-quality aluminum and copper alloys, combined with a pure titanium tube that runs through the coil. The titanium tube is made of CP-grade titanium, which is known for its excellent corrosion resistance and durability. Together, these components offer a unique combination of thermal efficiency, corrosion resistance, and durability that is unparalleled in the market.The China-based Company's industrial condenser coil and pure titanium tube come in a variety of sizes and configurations to suit different industrial applications. They are tested and certified to meet the highest quality standards, including ASME, PED, and ISO 9001. The company also offers custom-made solutions that are tailored to the specific needs of its customers. These solutions are developed based on extensive research, modeling, and testing to ensure their effectiveness and reliability in real-world applications.The industrial condenser coil and pure titanium tube from the China-based Company offer several advantages over traditional condenser coils and tubes. Firstly, they are highly resistant to corrosion and can withstand harsh operating conditions, including high temperatures, humidity, and chemicals. This ensures long-lasting performance and minimal downtime for maintenance or repairs. Secondly, they offer superior thermal efficiency, which translates into lower energy consumption and operating costs. Finally, they are environmentally friendly and can be recycled, which is in line with the company's commitment to sustainability.The China-based Company's industrial condenser coil and pure titanium tube has been widely adopted across various industries, including petrochemicals, power generation, marine, and pharmaceuticals. Some of the key applications include seawater desalination, air-conditioning, refrigeration, and heat recovery. The products have received positive reviews from customers worldwide, who praise their quality, reliability, and performance.In conclusion, the China-based Company's industrial condenser coil and pure titanium tube is a high-performance product that sets new standards in efficiency and durability. It is a testament to the company's commitment to innovation, quality, and sustainability, and is a testament to the Chinese manufacturing industry's expertise and capabilities. As demand for energy-efficient and sustainable industrial solutions continues to grow, products like the industrial condenser coil and pure titanium tube are poised to play a critical role in shaping the future of industry and commerce.

All You Need to Know About Stainless Steel Pipes: A Comprehensive Guide

Title: Leading Stainless Steel Pipe Manufacturer Celebrates Continued Success in the Market Introduction:As an industry leader in the manufacturing of high-quality stainless steel pipes, [Company Name] continues to dominate the market with its relentless commitment to excellence. With a history of producing top-notch products that meet and exceed industry standards, the company has achieved unprecedented success and cemented its position as a trusted supplier within the stainless steel pipe industry.[Company Name] has consistently prioritized customer satisfaction, innovation, and sustainable practices. With a dedicated team of experts, cutting-edge technology, and a diverse range of products, the company has continually evolved to meet the ever-changing needs of its clients. This comprehensive news article delves into the company's journey, its core values, and the reasons behind its continued success.History and Milestones:Established in [Year], [Company Name] has since grown from a small, local manufacturing facility to a globally renowned stainless steel pipe supplier. Over the years, the company has gained a reputation for its exceptional product quality, timely deliveries, and customer-focused approach. [Company Name]'s unwavering dedication to excellence has propelled them to the forefront of the industry, and its commitment to continuous improvement has ensured it stays there.Product Range and Innovation:[Company Name]'s extensive product portfolio includes a vast range of stainless steel pipes, catering to various industries such as construction, manufacturing, automotive, and plumbing. The company offers pipes of different sizes, thicknesses, and grades, enabling customers to find solutions tailored to their specific requirements. By utilizing state-of-the-art technology, [Company Name] ensures its products meet the highest quality standards and undergo rigorous testing procedures.To remain at the forefront of the industry, [Company Name] consistently invests in research and development. The company's team of engineers and technicians work continuously to innovate and improve their product offerings. This dedication to innovation has allowed the company to stay ahead of its competitors, delivering cutting-edge solutions and maintaining its stronghold in the market.Commitment to Sustainable Practices:[Company Name] recognizes the importance of sustainability in today's world and is dedicated to ensuring its manufacturing processes align with environmental best practices. The company adheres to rigorous guidelines to minimize waste generation, energy consumption, and carbon emissions. Through the implementation of sustainable practices, [Company Name] promotes responsible manufacturing and contributes to a greener future.Customer Centricity:[Company Name] places utmost importance on customer satisfaction, recognizing that its success is directly linked to its clients' success. The company's experienced sales and support teams work closely with customers to understand their unique requirements, providing personalized solutions and seamless support throughout the purchasing process. This customer-centric approach has fostered mutually beneficial, long-term relationships and led to a loyal client base.Furthermore, [Company Name] offers extensive pre and post-sales services, including technical consultations, material certifications, and prompt after-sales support. This commitment to providing comprehensive customer care has further enhanced the company's reputation in the market. Future Outlook:Looking ahead, [Company Name] will uphold its core values and relentless pursuit of excellence as it continues to expand its operations globally. The company plans to invest in enhancing its manufacturing capabilities, incorporating new technologies, and further diversifying its product range to meet upcoming industry demands and trends. Through sustained innovation, unparalleled quality, and unwavering customer focus, [Company Name] is poised to maintain its position as a trusted and preferred supplier in the stainless steel pipe industry.Conclusion:[Company Name]'s journey from modest beginnings to becoming a leading supplier of stainless steel pipes demonstrates its unwavering commitment to delivering quality products, exceptional customer service, and sustained innovation. By emphasizing customer satisfaction, embracing sustainable practices, and consistently raising the bar in terms of product quality and technological advancements, [Company Name] has positioned itself as a formidable force within the industry. With a bright future ahead, the company stands poised to continue its remarkable success story in the global market.