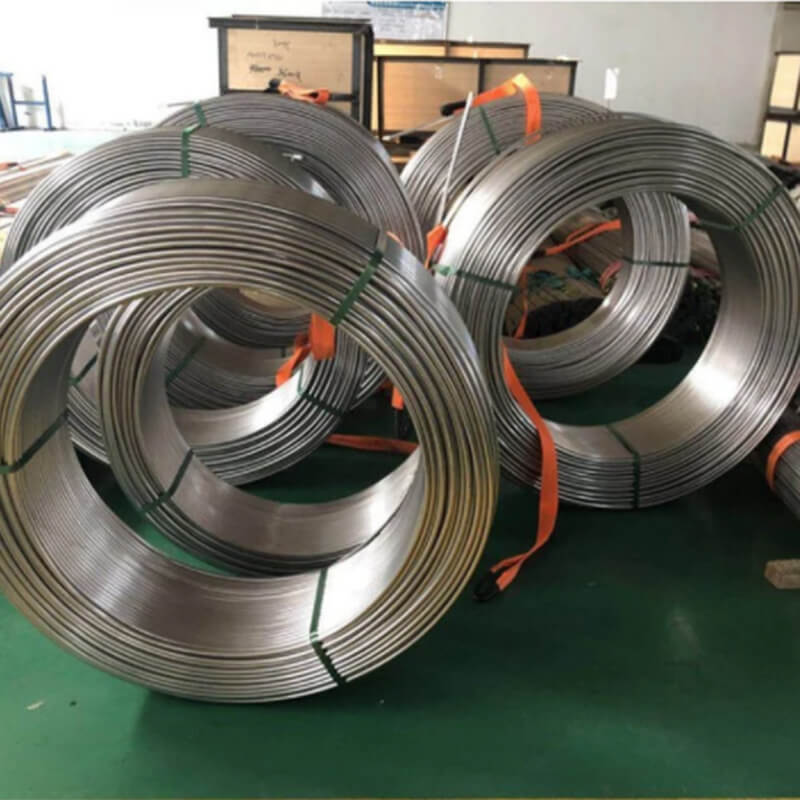

The traditional method of welding long stick tubing end to end or with fittings, it is a very labor intensive procedure., this welding process is very slow and costly, using coil tubing not only takes a fraction of the time, reducing labor costs, it also provides for a much safer and maintenance free installation. 1/4 stainless steel tubing coilis used for wide range of applications, applied for cooling and heating transferring energy in corrosive and non normal temperature environment, like food and beverage, oil and gas, medicine industry and so on, we manufacture and design coiled tubing to meet customer requirement in different sharps and purpose. Industrial stainless steel tubing coil applied for heat exchangers, boilers, oil, chemicals, fertilizers, chemical fiber, pharmaceutical, nuclear power and so on. Fluid stainless steel coil tube applied for beverages, beer, milk, water supply systems and medical equipment. Mechanical structure with stainless steel coil tube applied for printing and dyeing, printing, textile machinery, medical equipment, kitchen equipment, automotive and marine accessories, construction and decoration. 16/L (UNS S31600/UNS S31603) Chemical Composition % (Max.)16/L (UNS S31600/UNS S31603) Chemical Composition % (Max.)

The traditional method of welding long stick tubing end to end or with fittings, it is a very labor intensive procedure., this welding process is very slow and costly, using coil tubing not only takes a fraction of the time, reducing labor costs, it also provides for a much safer and maintenance free installation. 1/4 stainless steel tubing coilis used for wide range of applications, applied for cooling and heating transferring energy in corrosive and non normal temperature environment, like food and beverage, oil and gas, medicine industry and so on, we manufacture and design coiled tubing to meet customer requirement in different sharps and purpose. Industrial stainless steel tubing coil applied for heat exchangers, boilers, oil, chemicals, fertilizers, chemical fiber, pharmaceutical, nuclear power and so on. Fluid stainless steel coil tube applied for beverages, beer, milk, water supply systems and medical equipment. Mechanical structure with stainless steel coil tube applied for printing and dyeing, printing, textile machinery, medical equipment, kitchen equipment, automotive and marine accessories, construction and decoration. 16/L (UNS S31600/UNS S31603) Chemical Composition % (Max.)16/L (UNS S31600/UNS S31603) Chemical Composition % (Max.)| Cr Chromium | Ni Nickel | C Carbon | Mo Molybdenum | Mn Manganese | Si Silicon | Ph Phosphorus | S Sulfur |

| 16.0-18.0 | 10.0-14.0 | 0.030 | 2.0-3.0 | 2.00 | 1.00 | 0.045 | 0.30* |

| Grade | UNS | C(Max.) | Cr | Ni | Mo | Others |

| Alloy 825 | N08825 | 0.03 | 20 | 38.5 | 2.6 | Cu=1.7, Ti=0.7 |

| Alloy 625 | N6625 | 0.1 | 21.5 | >=58 | 9 | Nb=3.5 |